For many companies, sustainability can seem an insurmountable challenge. Even as the imperative to design environmentally sound processes and procedures becomes a greater priority, simply knowing where to start can be a difficult proposition.

As the current pandemic has made increasingly clear, however, sustainability and resilience go hand in hand. Whether it’s eliminating waste within your distribution network or securing the future of your business by circularizing your products’ end-of-life journey, greater sustainability means improved efficiency and agility — and therefore a greater number of options to choose from when crises do occur.

We recently had the privilege of sitting down with two sustainability powerhouses at our recent Supply Chain Leadership Summit: HP Canada and Walmart Canada. Here are some of the highlights I gleaned their eye-opening sessions.

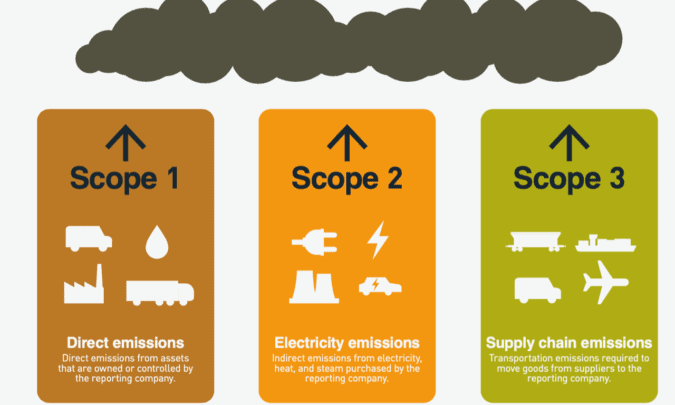

Logistics professionals often talk about emissions reduction programs in terms of scopes, with Scope 1 being the easiest to achieve and Scope 3 being the most difficult. In her talk, Edmonds mentioned that HP has disclosed its full carbon footprint, all the way up to Scope 3. When they did, she says they arrived at a startling realization. For HP, employees account for only 1% of the company’s total carbon footprint. Consumers using HP products are responsible for roughly 49% of emissions, and fully 50% of the company’s carbon footprint resides within the supply chain.

I loved Edmonds’ point that the simple act of measuring and tallying these numbers is often a critical first step in beginning to tackle them throughout the business.

“Being able to measure is important,” she said, “because what gets measured is what gets done in business, right?”

This goes hand in hand with her assertion that the fastest way to green your business is often to purchase from one that’s already green. Simply by revisiting your purchasing and procurement practices and adding some sustainability criteria, you can make a tremendous difference in your company’s overall carbon footprint at all levels of the supply chain. In short, make your mantra to buy the most sustainable good from the most sustainable supplier, and you will be well on your way to enacting major reductions in corporate carbon footprint.

Another outstanding example of the drive to Scope 3 emissions tracking came from another guest at our recent leadership conference: Walmart Canada’s Vice President of Transportation Francis Lalonde. Walmart began its push toward Scope 3 back in 2010, after more than seven years of pursuing initiatives designed to monitor and reduce emissions within its stores, offices and corporate fleet. Walmart’s Scope 3 initiative, codenamed “Project Gigaton,” sought to eliminate one billion metric tons of greenhouse gas emissions from the company’s sprawling corporate supply chain — and it promised to do so by 2030.

What makes Scope 3 to achieve is the fact that it targets emissions originating from outside the organization itself, focusing instead on suppliers, manufacturers and transportation partners. Rather than being a management and innovation challenge like Scopes 1 and 2, mastering Scope 3 requires convincing partners to place a priority on their emissions levels. It’s a challenge where a massive, well-known company like Walmart is much more likely — perhaps even necessary, in the early stages — to achieve success.

But this doesn’t mean that Walmart has taken a step back from its push to expand sustainability within its own internal operations. During his appearance at FourKites’ Leadership Summit, Lalonde mentioned his company’s journey to achieving a fully-electric fleet, a subject he said was near and dear to his heart.

“We’re at the point where we’ve cranked up our orders from 40 to 130 Tesla trucks,” Lalonde said. “It’s one of the largest orders in the world. We’re on a journey to be alternately powered by 2028 within the Canadian business. Our first trucks are scheduled to arrive by early next year, so we really want to be ready for that.”

Edmonds mentioned that reducing emissions on the road was a key goal for HP as well, stating that all HP shipments in North America are now done through SmartWay-approved carriers. SmartWay is a program designed by the US Environmental Protection Agency and employs techniques such as anti-idling policies, low-friction tires and more to reduce the carbon footprint of trucks on the road. Compared to the average Class A semi truck, a SmartWay truck operates at about 18% higher fuel efficiency, which adds up to a considerable difference for major companies like HP, both in terms of fuel cost and environmental impact.

. . . . . . . . . . . . . . . . . .

FourKites’ Supply Chain Leadership Summit was full of many other fascinating viewpoints and compelling insights on future-proofing and improving sustainability within the enterprise supply chain, and it was inspiring to hear speakers like Edmonds and Lalonde lay out the ways that they are working to green their supply chains each and every day.

Especially as consumer and investor attention paints corporate sustainability in ever-sharper focus, the companies that invest in dreaming up new and creative ways of slashing their carbon footprints will be the ones that succeed in today’s competitive business landscape.

From 3-D printing replacement parts to custom-growing wood composites as a replacement for plastic packaging, our speakers were full of new and innovative thoughts on the supply chain of the future, and I highly encourage that you give it a listen. You can catch the recap of FourKites’ Supply Chain Leadership Summit here, and make sure to check in with the FourKites Sustainability Center of Excellence from time to time for fresh news and updates from the world of supply chain sustainability!